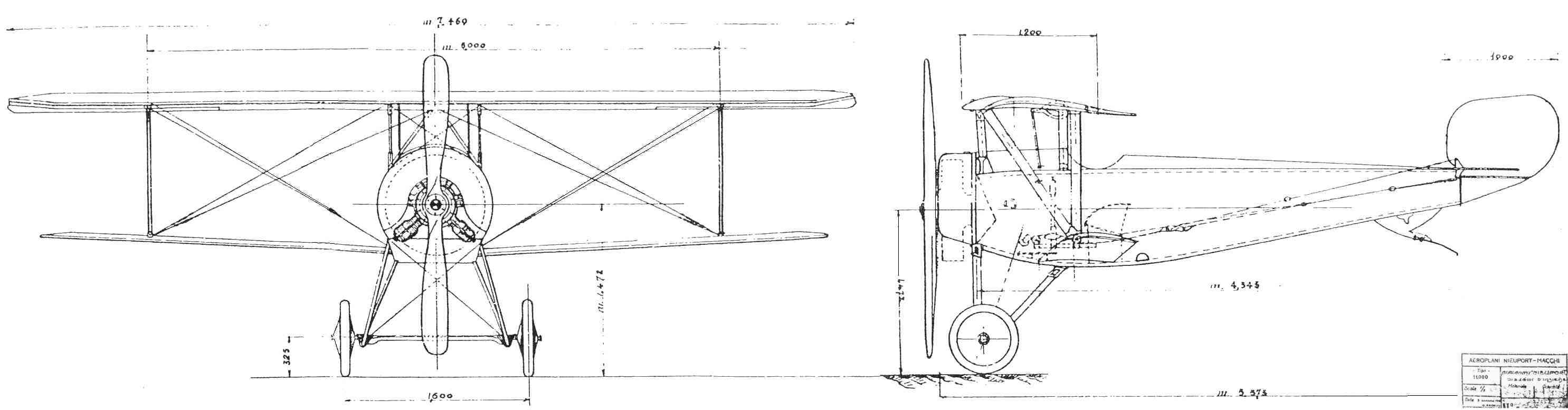

• Building a Nieuport 11 replica •

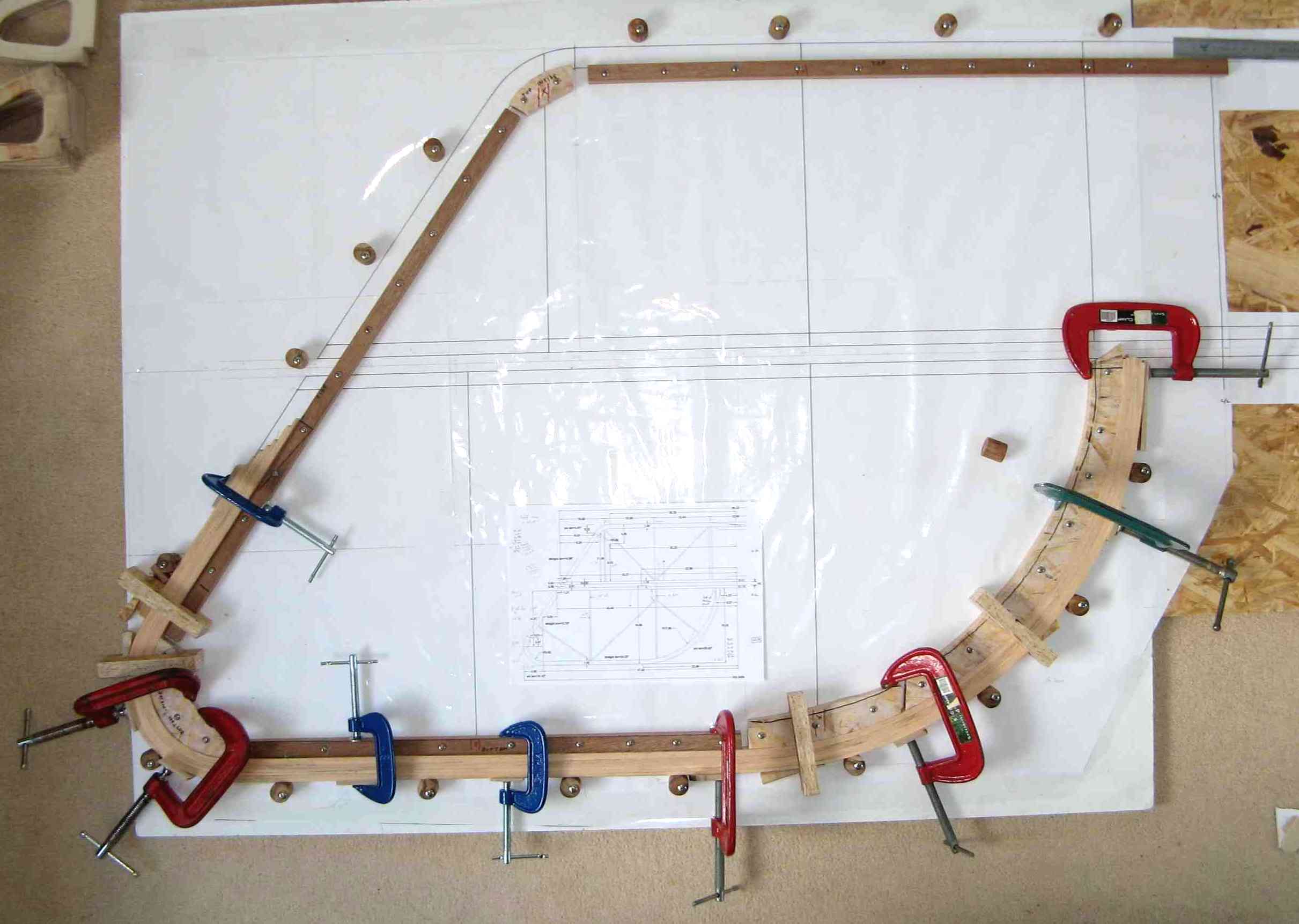

As with the rudder, the horizontal stabilizer has a large curved frame that needs to be laminated.

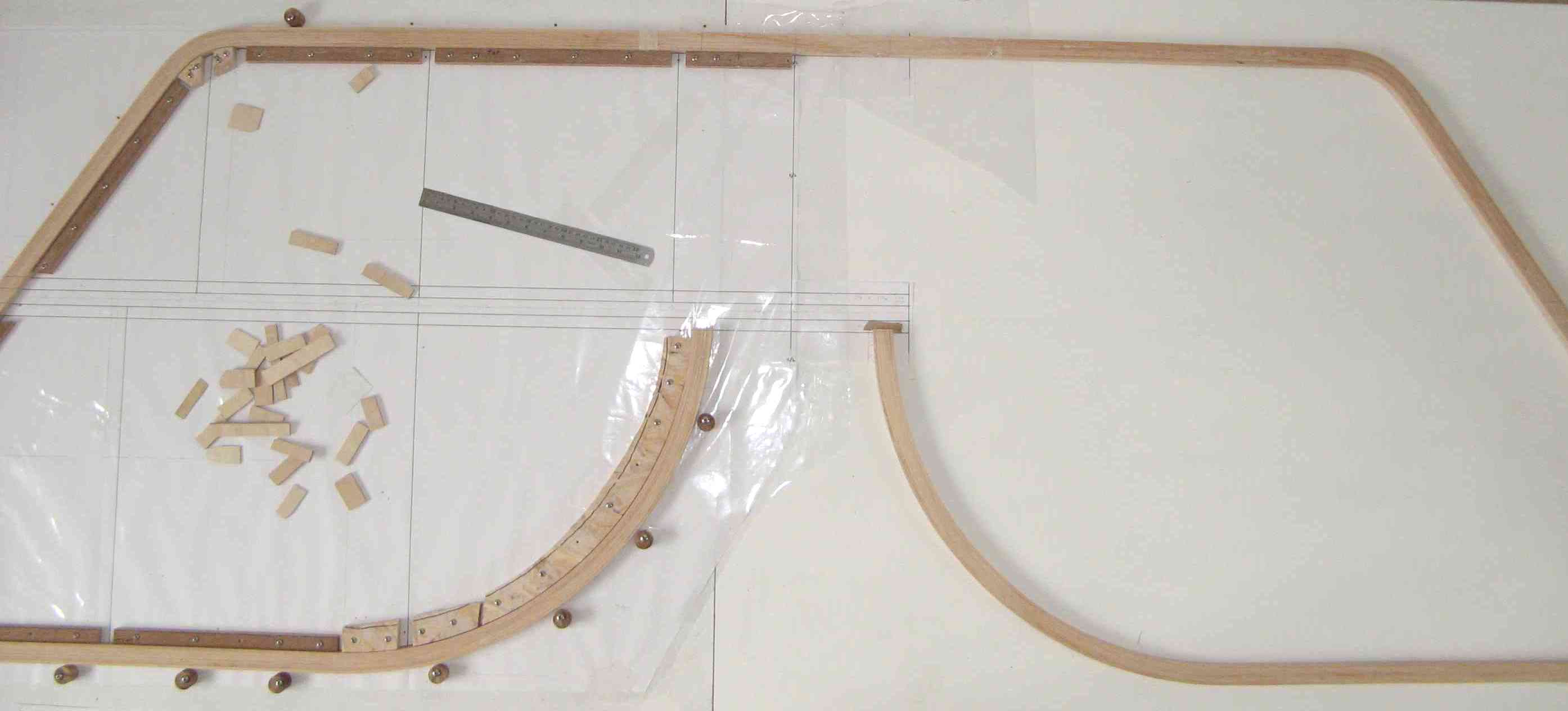

The first stage was to produce a jig around which the timber could be laminated.

A paper pattern was produced and attached to a sheet of 18mm MDF. Plastic film was then laid over the pattern to prevent damage to the pattern and to stop glue sticking to the paper.

MDF patterns were then made to the outline of the internal curve of the rudder frame and screwed to the base.

Cams were made by cutting an old broomstick into 1" sections and drilling an off-centre hole through each one.

Tightening the screw would thus push the cam against the laminations or release them accordingly.

Strips 3/4" x 1/8" were steamed for about 20min and then bent around the frame.

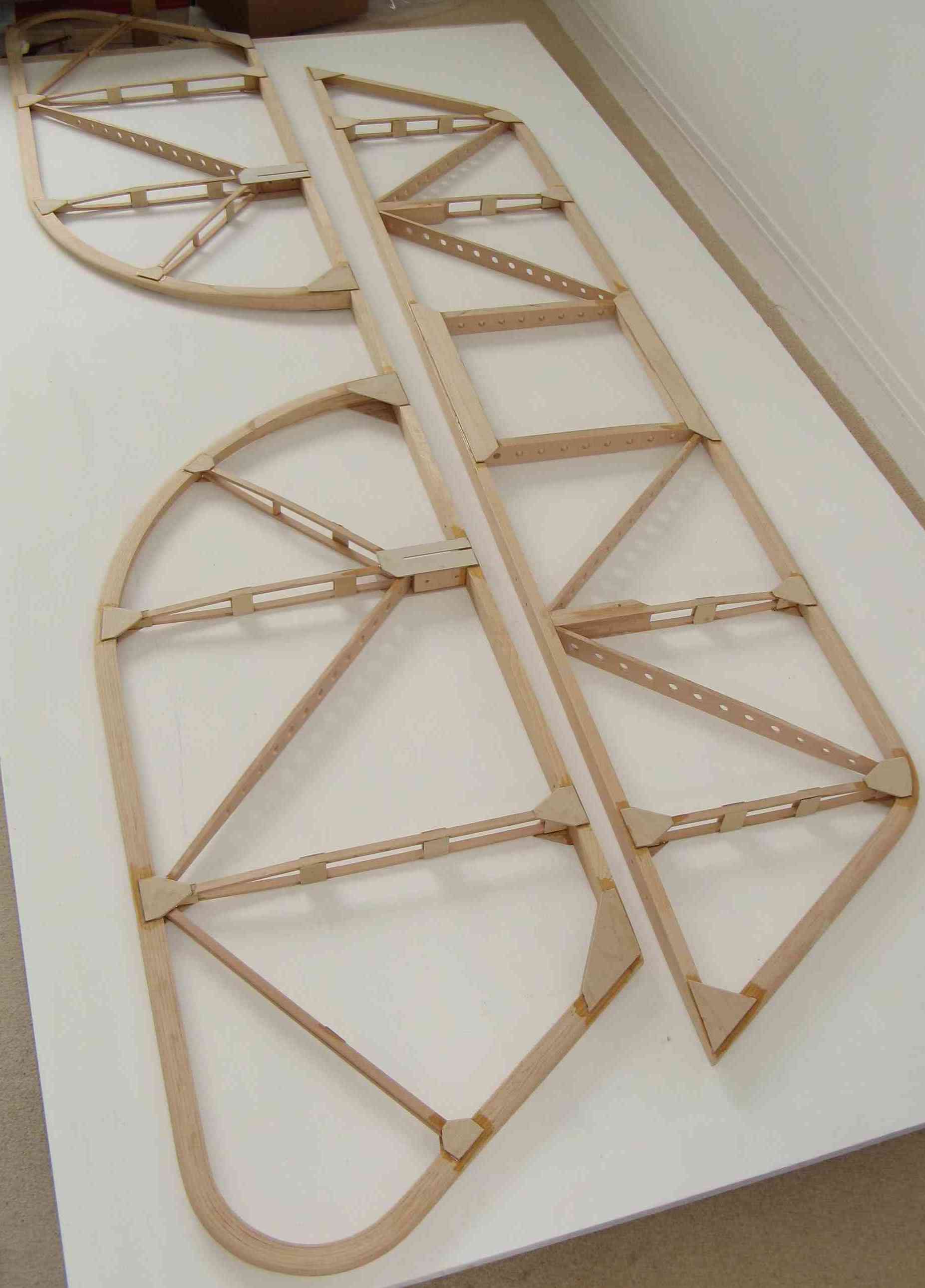

The frame had to be built up out of four sections, and scarfed after laminating

The laminations were left in the jig for several days and allowed to dry. A dehumidifier was run to help dry the room.

The individual pieces were then separated and given several further days to dry out.

The laminations were then glued using Aerolite adhesive.

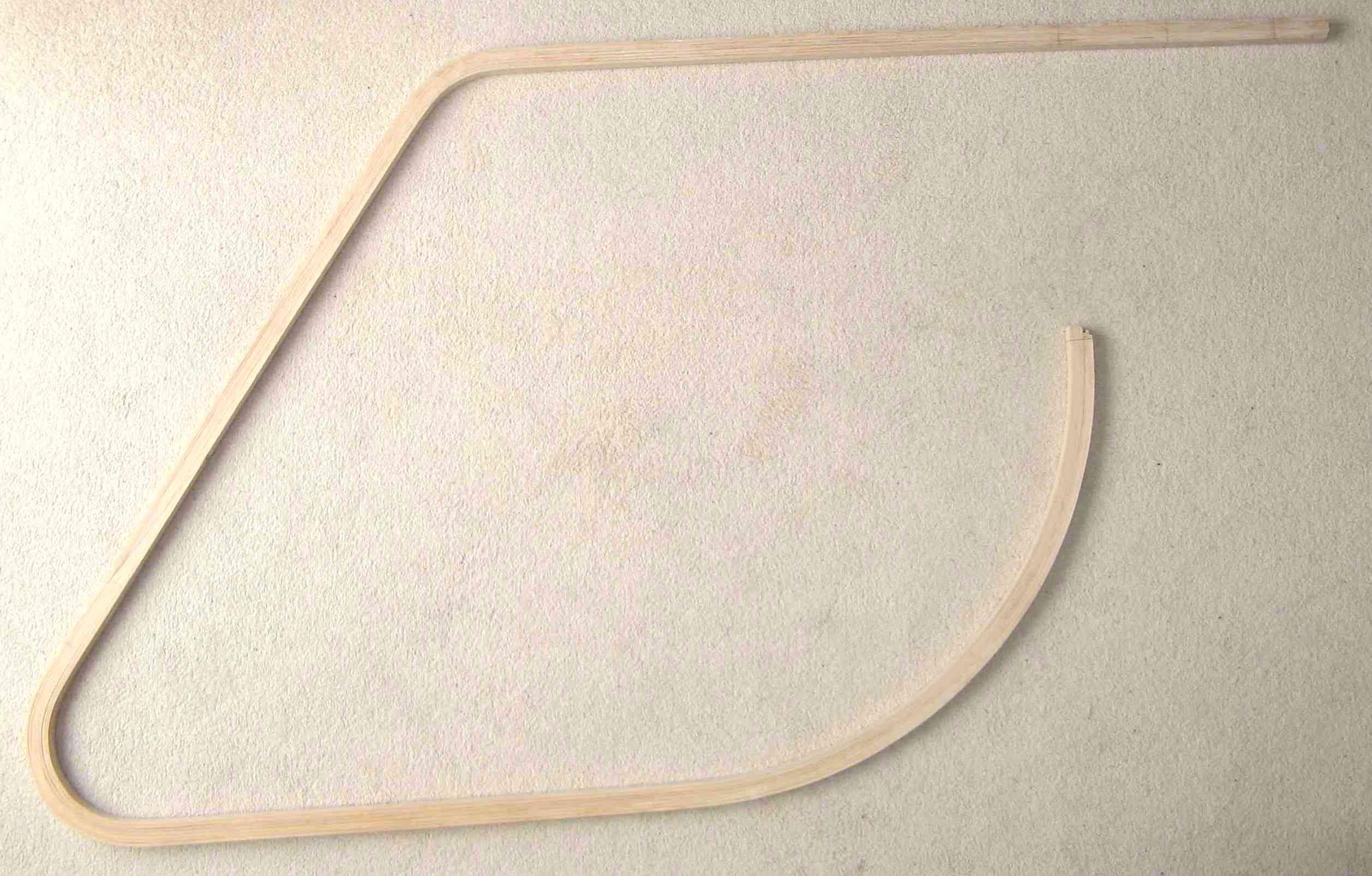

One half of the frame.

The two halves were then scarfed together using a 1:12 scarf.

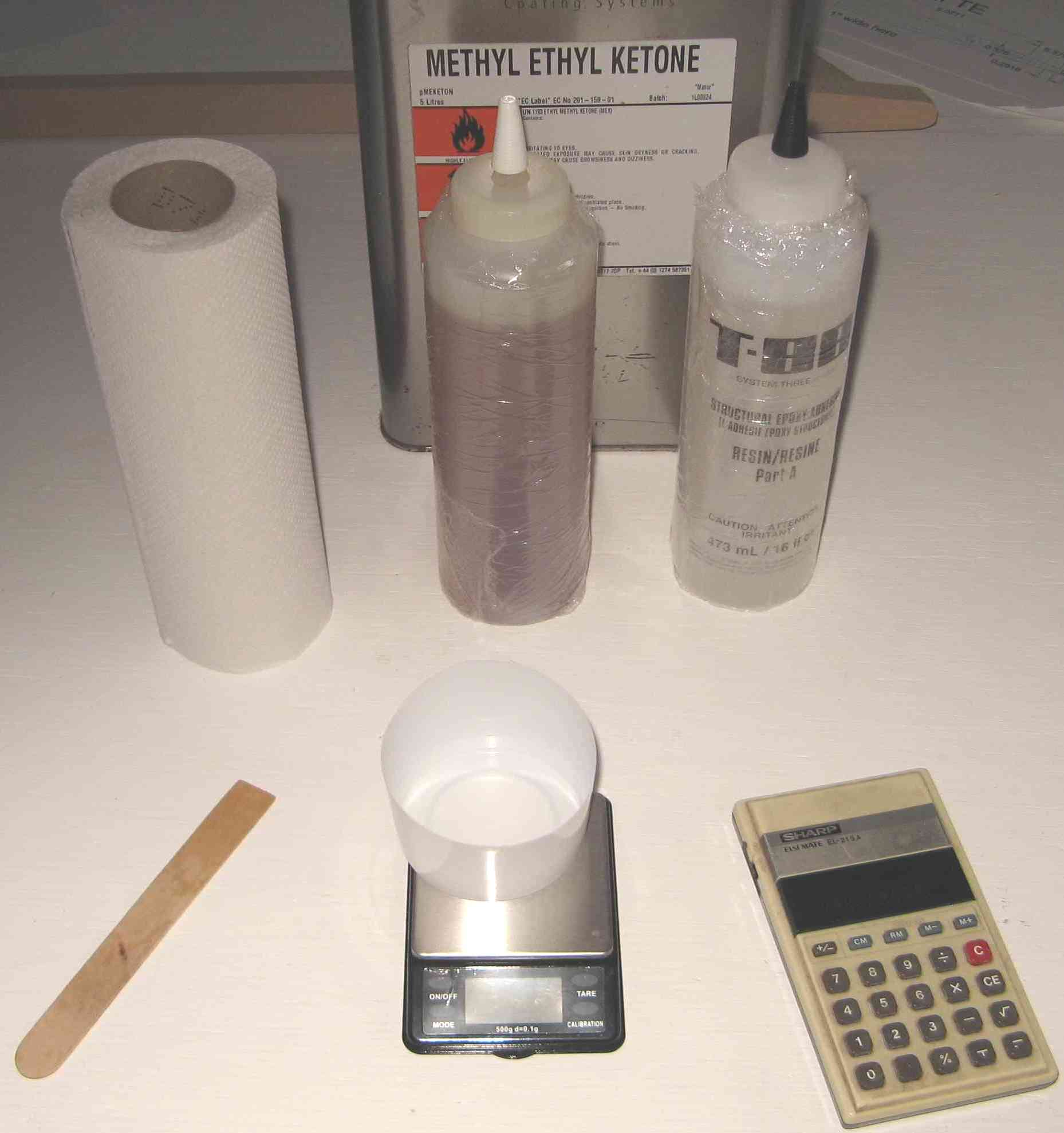

Aerolite glue was used for laminating and scarfing, and T-88 epoxy for the rest of the glueing.

Again, lots of clamps required.

The epoxy has a limited working time and so organization is paramount.

The glue can be measured by volume or weight. I used the weight method: 100 parts expoxy to 83 parts hardner.

Old yoghurt containers and lids were saved up for several months before commencing the project. The pots were cut down to give a useful sized container, and the lids used for small volumes.

A jewellers scale was used to weigh the epoxy. Using a calculator this was multiplied by 1.83 and hardner added until this weight was reached.

The epoxy was mixed using tongue depressors which can be purchased cheaply in bulk. The ends of the sticks were sanded square at one end and slightly rounded at the other - the latter to obtain glue gussets where required.

Tissues and MEK were on hand to clean up any drips. It is important to clean up any excess epoxy before it sets as it is very hard to remove afterwards. Apart being unsightly and unprofessional, every bit of surplus glue adds weight and achieves nothing.

The spars and ribs were added.

Gussets and cap strips were glued on and the leading edge and trailing edges sanded.

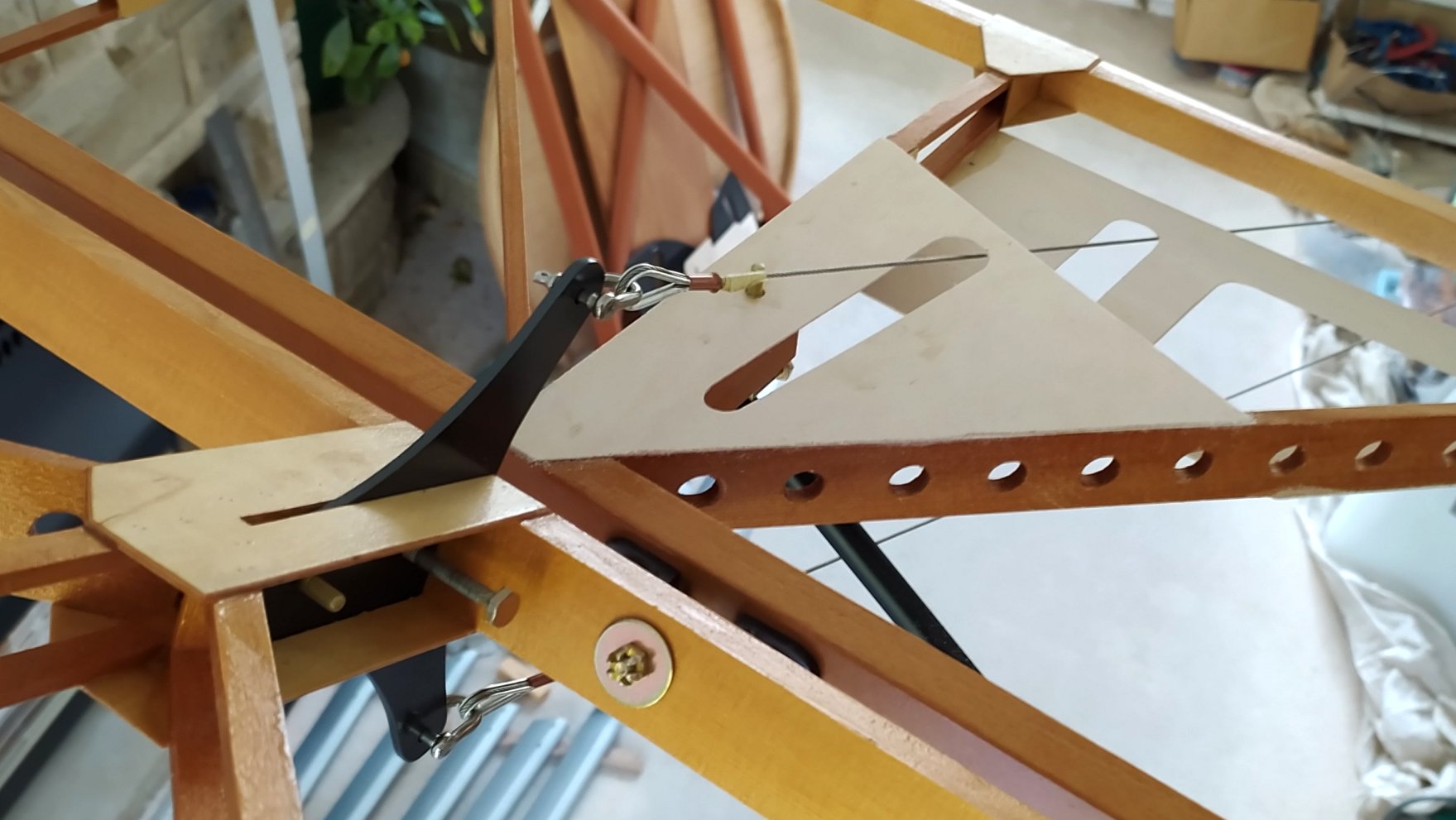

The elevator horns were fabricated from .125" 6061-T6 aluminium sheet.

The parts were primed with etch primer and sprayed with grey primer.

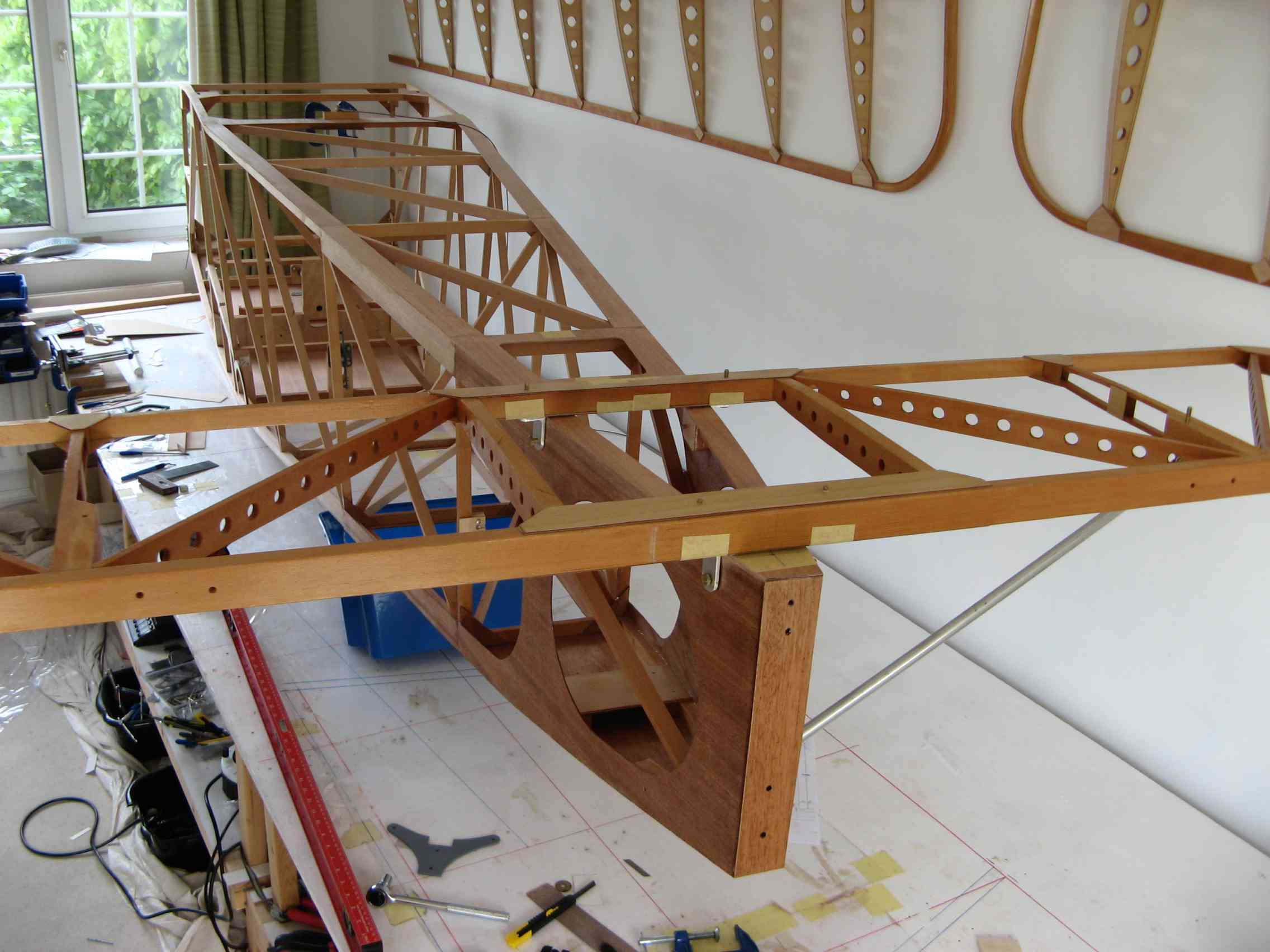

The fuselage and finished horizontal stabilizer were carefully levelled and attachment brackets drilled either side of the fuselage fore and aft. A wire was attached on the centre line of the fuselage near the cockpit and run back to each stabilizer tip to check the distance was the same and thus the stabilizer was perpendicular to the centre line.

The brackets allow the stabilizer incidence to be adjusted in order to trim the aircraft. Based on experience with aircraft built in the US and elsewhere to Circa plans it is expected that up to 2 degrees incidence may be required. This will be determined during the test flying stage.

The stabilizer is supported by struts at either side of the rear fuselage. These are 1/2" aluminium tubes with inserts, attached via eyebolts.

The insert at one end of the struts was rivetted in place. The other end will be permanently attached when the final rigging is done.

The elevator cables run through gussets which support the fabric top and bottom of the stbilizer.

Elevator cables are attached to the horn with shackles. These will be safety wired after assembly.